We support diversifying needs for products with high quality, quick delivery and low costs.

We provide the high technical strength to process various materials.

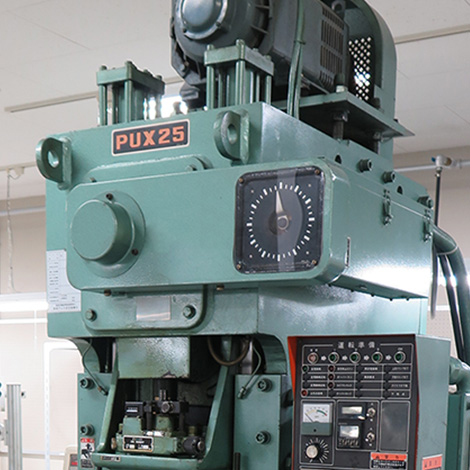

Pressing

High quality and high precision production line that enables high precision processing for various materials by handling from single pressing machine to large pressing machine freely

Characteristic

- Processing machine/equipment suitable for each materials

- High speed continuous production line

- Processing plan depending on needs including from inexpensive Thomson type to high precision mold

Intoroduction of the Press Processing Technology

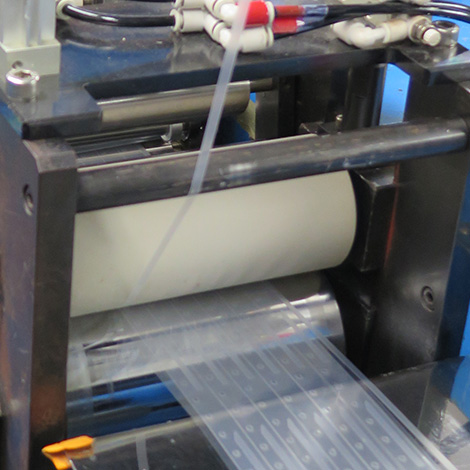

Combined Processing

Production that enables short lead time by attaching various materials automatically by combining pressing machine and laminator

Characteristic

- Multi-layer lamination for laminates that cannot be laminated manually by combined machines

- Support various patterns from whole surface lamination to precise partial lamination of tapes

- Automatic cutting detection sensor depending on number of products/sheets

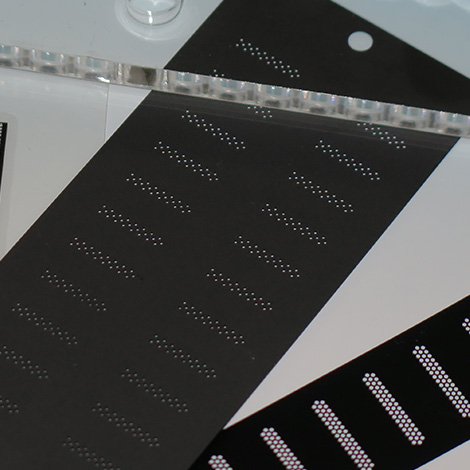

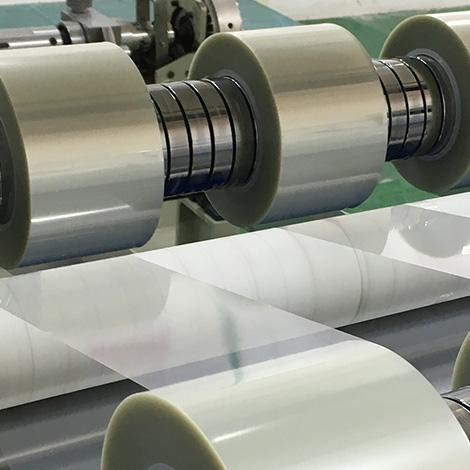

Rotary Processing

High speed processing by continuous rotation and continuous pressing

Improves yield by the through processing from processing to automatic accumulation without touching material

Characteristic

- Etching, Embossing roll type

- High-efficiency and speedy production by continuous rotation and pressing

Laser Processing

Cutting, punching and engraving of various materials by laser

Characteristic

- Die is not necessary

- It is possible to process various resin materials

- Speedy designing by DXF file

Intoroduction of the Laser Processing Technology

Trial Processing

"Internal design/development" to support customer needs

We support from one piece of trial product for various demands by using various molds and jigs

Characteristic

- Support make-to-order production of diversified small-quantity models

- Minimum lead time system by material stock of various kinds and the inspection connected directly from processing

Bending

Can support bending of thick film or strong film that is hard to bend to any angles with a heating bending machine

Characteristic

- Thermal processing that stabilizes bending angles

- Bending angle design by calculating the restoring force based on the abundant experience

- We support minute bending and complicated/multiple bending

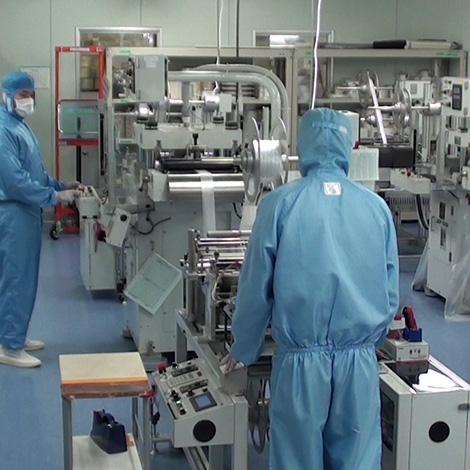

Clean Room

Facility whose contamination by airborne particles in air is controlled

Fully equipped clean room (Yamanashi Seimitsu)

Characteristic

- Implement all the processes from material injection, processing to packing in the clean room

- Supports pressing machine and special processing depending on applications

- Air cleanliness standard: FED-STD-209D

- Equipment design: Class 10,000

Other

We support slitting/pasting to desired shapes and other processing of functional materials including various plastic films, optical films and metallic foils etc.

Characteristic

- It is possible to apply various laminates including heat laminate, dry laminate and partial laminate etc.

- We support various demands including slitting at the normal environment, micro slitting in a clean room, mold injection, vacuum forming and combined machining with a metal.

Quality Assurance

Stable Quality Assurance System

We make the best efforts for the quality assurance of the products that we manufacture and the materials to meet customer requirements quickly.

Characteristic

- 600 times zoom available, Full automatic measuring by program Image measuring machine and 3D measuring machine are equipped

- X-ray fluorescence spectromer for material composition survey (ROHS)

- Adhesion test (180° peeling test / Tension and compression test)

- Test room whose temperature and humidity are fully controlled

- Quick support various tests

Measuring Equipment

- NC image measuring machine

- 3D measuring machine

- Dispersive X-ray fluorescence spectrometer

- Tension and compression tester

- Projector

- Thermostatic chamber